What Does Manufacturing Do?s

Wiki Article

Additive Manufacturing - An Overview

Table of ContentsGetting My Additive Manufacturing To WorkNot known Details About Die Casting Manufacturing Can Be Fun For AnyonePlastic Manufacturing Fundamentals Explained10 Easy Facts About Die Casting DescribedUnknown Facts About Plastic ManufacturingIndicators on Lean Production You Need To Know

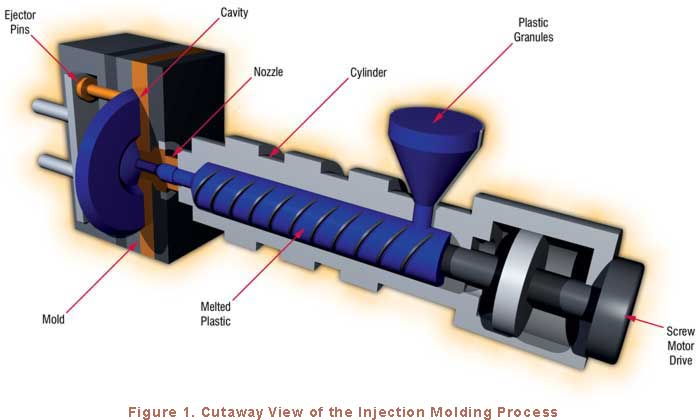

It's additionally feasible to utilize insert molding to include plastic components over existing parts constructed of other materials. The basic concepts behind the injection molding procedure may seem easy, but in fact, it is a really difficult process that requires the appropriate devices and the right competence. When it is performed appropriately, injection molding can constantly create exceptional outcomes also for the most tough manufacturing projects.

Simply as with any production strategy, there are benefits as well as downsides that can put on various scenarios, and also only by understanding them can you make a notified decision. Keeping that in mind, let's review a few of the most considerable advantages and disadvantages that injection molding can use. Pros, Initially, allow's look at the pros of selecting to produce with an injection molding device.

The Basic Principles Of Lean Manufacturing

That means that with every run, you can produce a part that is identical to the one preceding it, over and also over once more. As you can picture, this kind of accuracy is essential in mostly all markets, and also specifically in those that can not jeopardize on quality, which is why shot molding is preferred in highly-demanding fields like aerospace and automobile.That means that you can not only decrease the possibilities of human error to a minimum, however also have the device create parts at a constant rate and also a high gratification price. Expense Efficiency, For the most component, shot molding is just one of the most economical solutions for producing components that you can discover.

Variety of Materials, If there's something that shot molding really succeeds at, it's the capacity to personalize the materials as well as coatings according to virtually any kind of kind of needs. You can select plastic, polycarbonate rubber, chemical immune plastics, eco-friendly, and also several others, so just make sure to figure out what you require from the component as well as you'll have lots of choices.

The Best Guide To Hon Hai Precision

Eco-Friendly, Lastly, in a globe where understanding the atmosphere is extra essential than ever, shot molding can be helpful because it produces virtually no waste. Every bit of material that isn't used in the mold and mildew can be repurposed and also used in future projects. Disadvantages, Since we have actually checked out why shot molding is so reliable, allow's look at several of its imperfections to provide you a much more well-shaped photo.Prior to you can in fact manufacture, you will need to create and develop the mold itself, and also that can take numerous hrs as well as a lot of workforce to perform appropriately. Still, despite the fact that this procedure can be intricate, once it's done, you can use the mold to produce hundreds of components swiftly.

Manufacturing Industries - Truths

Applications of Shot Molding, When producing parts, precision linked here and cost-effectiveness are two of one of the most important factors to consider that a lot of firms are trying to find. That's why it's not unusual that a procedure such as shot molding has come to be so prominent and has actually been made use of both for smaller sized runs, along with massive production of get rid of tight resistances.Food & Drink, As we pointed out previously, shot molding provides firms the ability to create components from a variety of products. Which's very crucial in an industry such as food & beverage because it requires to adhere to a variety of guidelines regarding the safety of food containers.

This, combined with the reasonably inexpensive of manufacturing, makes injection molding ideal for generating parts such as food containers, beverage caps, filtering parts, and also a lot more. Building Parts, One more sector that utilizes shot molding modern technology is building as well as building and construction, where the tailor-made and also intricate plastic parts play an essential role in the procedure of building residences as well as frameworks (plastic manufacturing).

What Does Die Casting Do?

A number of the integral clinical gadgets such as heart pumps, various screens, in addition to a variety of clinical instruments all depend on the accuracy of injection molding, which makes the technology irreplaceable in the field. How to Select Shot Molding Solutions, Despite the fact that injection molding can be unbelievably beneficial in a large range of markets, in order for any one of that to matter, you must pick a reliable and also knowledgeable solutions service provider that can take your vision and also transform it into truth.

As you currently recognize, the procedure of developing and developing the mold and mildew can be challenging, so you require experienced professionals that can aid you conquer any hurdles that you experience. In addition to seasoned personnel, the supplier ought to likewise have one of the most innovative shot molding equipment modern technology since that plays a vital duty in how accurate the parts can be, how swiftly they can be generated, and the length of time will it take to begin the manufacturing procedure.

Not known Factual Statements About Additive Manufacturing

When you need to scale up production, you don't intend to need to search for a new service provider merely due to the fact that the firm turned out to be incapable of doing larger runs.Image: Parts before sintering (back) and after sintering (front). (Image courtesy of PCC Advanced) Blade clamp for a power tool: Changing a multiple-component assembly with a steel injection molded part. (Image thanks to Kinetics Inc.) To make a complex component in metal, you can cast it, or machine it or injection mold it.

Injection molding by blending steel powder with plastic, molding it and after that eliminating the plastic and sintering the component. The procedure is called metal shot his response molding (MIM), or occasionally powder injection molding (PIM), and it can create complex components in a large range of metals, consisting of steel, stainless-steel, as well as also high-temperature alloys. lean production.

Unknown Facts About Oem

Industries that currently make use of MIM parts include aerospace, clinical, electronics, weapons and customer products. You might be familiar with powdered steel, or PM, components, particularly as bearings, bushings and tiny equipments.Report this wiki page